SPEED

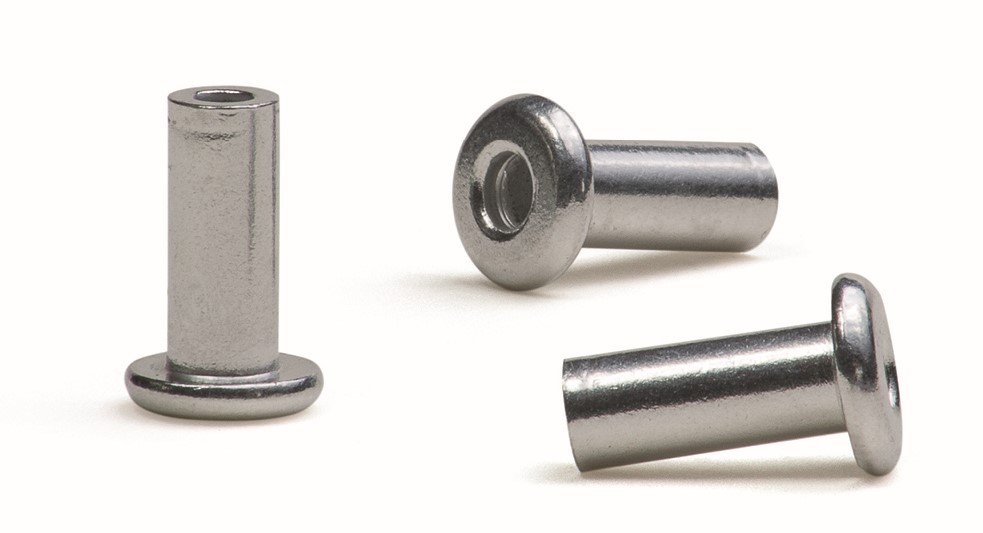

RIVETS

Speed rivets are serial fasteners designed for fast and precise joining of all types of materials, such as metals to plastics or electronic components.

CHARACTERISTICS

These fastening systems are manufactured in aluminum, steel and stainless steel.

These rivets do not have a mandrel assembled and are supplied on a paper strip to aid placement in the riveting machine.

- Fast and high precision assembly. The assembly cycle time does not exceed 2 seconds.

- Increases productivity as there are no interruptions and up to 60 rivets can be set per minute.

- There is a great diversity of materials, lengths and diameters.

- Do not deform riveted surfaces (painted, enameled, etc.).

- Radial expansion during installation ensures excellent hole filling.

- There is no mandrel, so there are no noises or mandrel sticking.

- Its bulged end offers high joint tightness and good shear strength.

DIFFERENCES BETWEEN BSR AND BSV

Both rivets are set in series (preloaded in paper strip) with a single mandrel system. Each rivet is automatically fed into the tool nosepiece and is ready to start a new riveting cycle.

The BSR has a bulging protrusion on their body and are available with dome and countersunk head, and the BSV has a straight body shape.

WHICH APPLICATIONS ARE SUITABLE FOR THIS TYPE OF RIVET?

Speed rivets are used in the automotive industry to join metals to soft materials, as well as in electronics, furniture, stair manufacturing and light metal constructions in general.