01

Supplier Selection

Quality control

Raw material inspection and validation

02

Wire Transformation

Controlling and guaranteeing the necessary requirements for the stamping process.

03

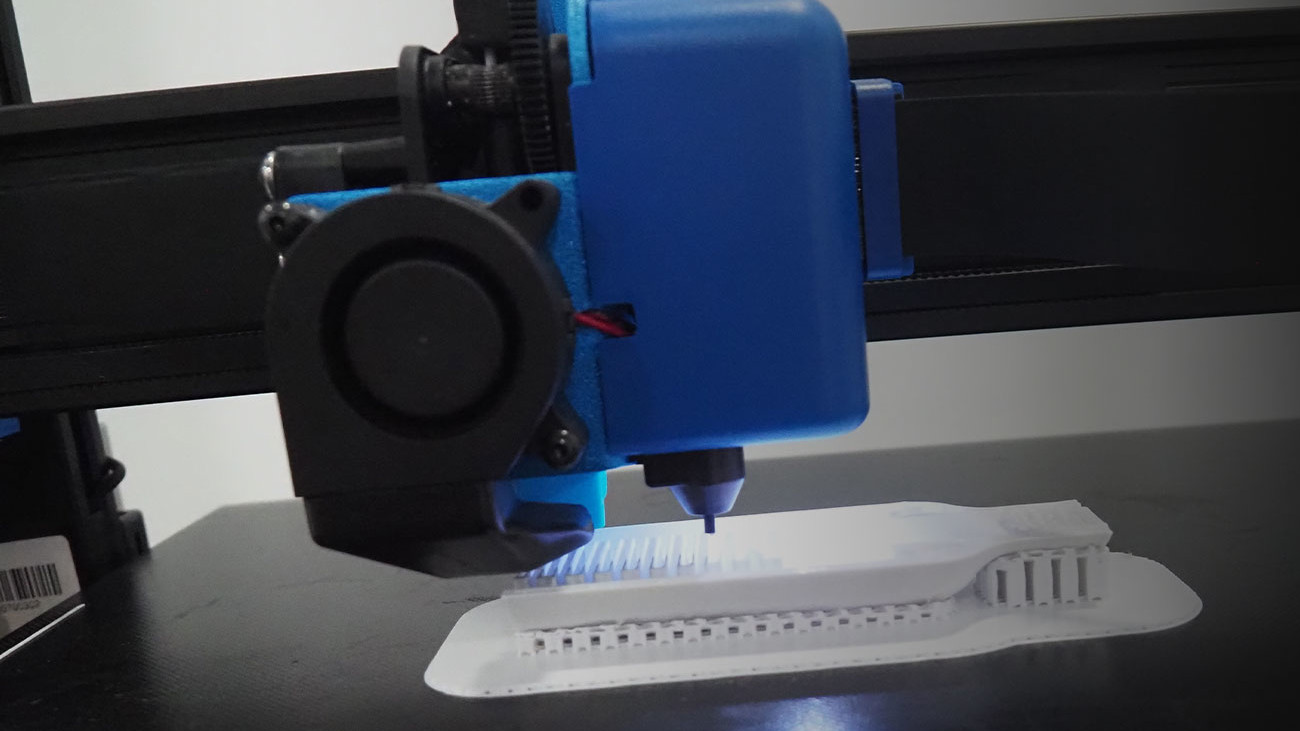

TOOLING DESIGN AND SIMULATION

Design of dies and other critical components for the forming process according to design requirements.

04

Forming

Forming of the different components according to the established design.

05

Centrifuging and Washing

Preparation of parts for subsequent heat treatment.

06

Heat treatment

Set of thermal processes defined during the design of the part, and whose objective is to achieve the mechanical properties of the materials involved in it.

07

Secondary operations

Grooving and/or threading, washing, centrifuging and polishing: The process of adding value to the part design includes different steps depending on the part design.

08

Surface treatment: Zinc plating, delta-seal, prepared for painting, anodizing…

The design of the part is subject to multiple requirements such as different anti-corrosion treatments depending on the final application and aesthetic color options.

09

Assembly:

The different components of the design are integrated into a final product that provides the necessary value for the CUSTOMER’S fastening solution.

10

Inspection:

The final production of the assembly can be 100% controlled, according to the requirements of our customers, by means of optical vision control equipment.

11

Packaging:

Control and adaptation of our packaging to the regulatory requirements and possible needs of our customers.

12

Expedition:

Preparation and control of all shipments, in order to meet the requirements of our customers.