There are many types of rivets and thanks to this diversity fixing problems, can be solved in all industries.

Within each of these sorts of fixings, there are an infinity of variables: different head, material, size, and therefore, specific benefits.

We are going to know what a rivet is and the types of fixings that we can find in the market:

WHAT IS A RIVET

The rivet is a permanent fixing system used to join two elements of the same, or different material.

BLIND RIVET – TYPES OF RIVETS

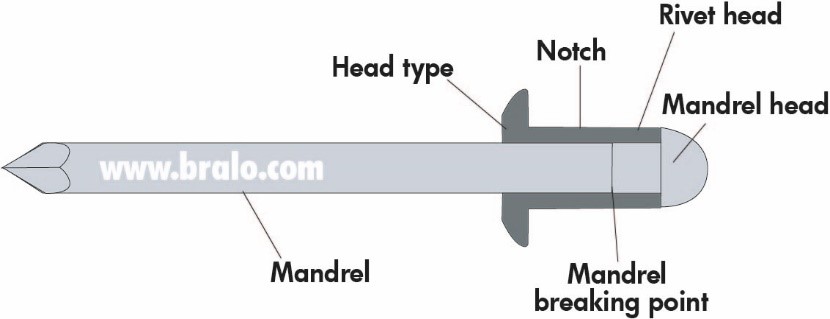

This type of rivet only has access from one side. Since the back is “blind”, it therefore cannot be seen. The blind rivet is made up of two parts, a head and a mandrel of the same or different material.

These are the parts of the rivet that help us understand its physiognomy:

HOW TO RIVET A BLIND RIVET

The riveter deforms the mandrel by mechanical traction until the shank breaks and is fixed in the application.

TYPES OF BLIND RIVETS

At BRALO we have the most extensive range on the market since we have more than 12 families of rivets depending on the use for which they are going to be used:

- Standard Rivet

- Peeled rivet

- Rivet Multigrip

- Hardvex Rivet

- Rivet Versagrip

- Trebol Rivet

- Rivet S-Trebol WP

- Sealed Rivet

- Grooved Rivet

- Structural Rivet

- Multilock Rivet

- Hardlock Rivet

- Hardgrip Rivet

- G-Bra Rivet

In BRALO you can find 3 types of heads:

- DOME HEAD: it is the most versatile head and provides enough support surface to retain all types of materials, except the most brittle.

- LARGE HEAD: thanks to its support area, double the support surface is achieved, especially for soft and brittle materials.

- COUNTERSUNK HEAD: it is the head that allows a thicker rivet and achieves a flat surface, without projections.

In the BRALO catalogue, you can find out the types of rivets and here you can see the GUIDE on how to choose the ideal rivet.

RIVET MATERIALS

BRALO rivets are manufactured with high quality materials to ensure that they adapt to the standards of different industries.

Each type of rivet can be made of materials such as aluminum, steel, A2 or A4 stainless steel, monel, copper…

RIVET FINISHES

All rivets can be lacquered to suit the color of your application, such as ventilated facades, automotive, furniture …

We have more than 150 colours according to the RAL chart and we can make lacquers on request.

Our company have a wide range of organic, anodized and zinc plated coatings that improve corrosion resistance.

We work alongside the client with custom designs that are tailored to their specific needs.

OTHER TYPES OF FIXINGS:

SPEED RIVETS

Rivets are also considered those small fasteners that are supplied in a paper strip, they are quick rivets.

These fasteners are used for high-speed assembly of parts, such as soft metals, as they do not deform the surfaces.

LOCK BOLTS

It is a rivet made up of two parts, one part is a slotted mandrel with a head, and then a moving part, the collar.

Both pieces are assembled and fixed to applications where high tensile and shear strength is required.

DRIVE RIVET

The drive rivets are ideal for fixing sheets and profiles to soft materials and also do not require through holes.

The stainless steel mandrel is driven by a hammer into the body of the rivet, thus being resistant to corrosion.

The rivet opens into three parts within the application and thus achieves a solid grip within the application.

SOLID AND SEMITUBULAR RIVETS

At BRALO we manufacture solid, semi-tubular and stepped rivets, and, different variants that are designed to adapt to the needs of manufacturers.