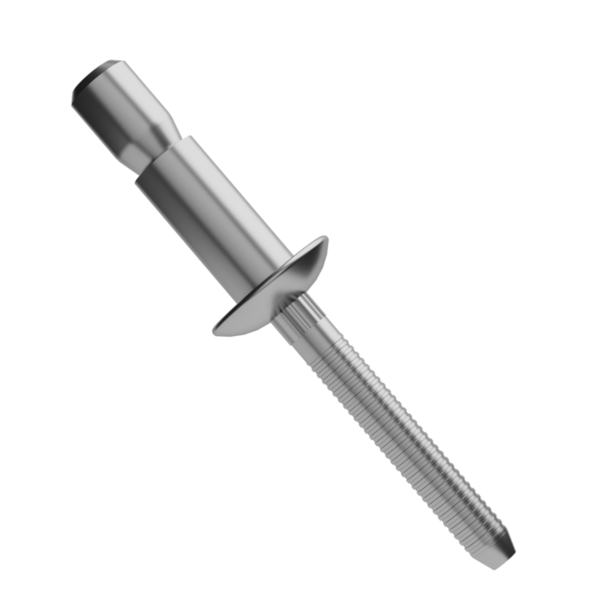

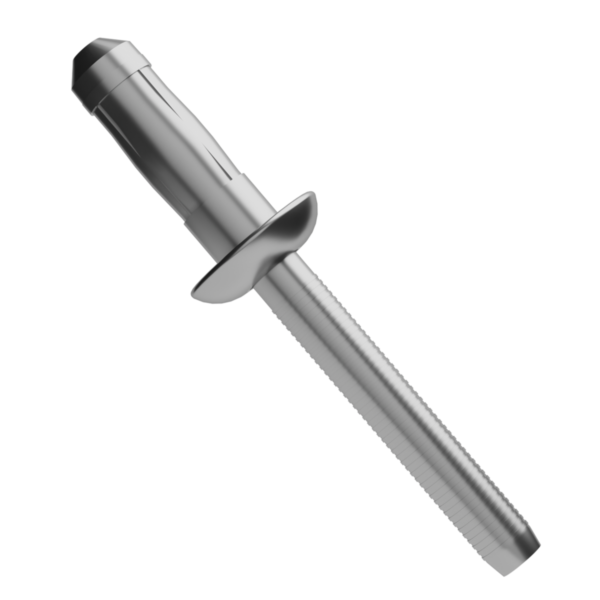

STRUCTURAL

RIVETS

Structural rivets are fasteners with high mechanical properties of both tensile and shear strength, ideal for structural applications.

It is the optimum joining method that guarantees fastening in the most demanding applications on the market.

MAIN CHARACTERISTICS OF STRUCTURAL RIVETS

- High tensile and shear strength.

- Ideal for applications with single-side access.

- Fastening with structural behavior to work in different thicknesses and achieve a homogeneous riveting.

- Good hole filling by radial expansion of the rivet, allowing to compensate for uneven, misaligned and oversized holes.

- Solid and high quality joint. Vibration resistant due to internal locking of the mandrel.

- Its high strength allows for fast assembly of pieces with large separations.

- It is a rivet of high durability and excellence.

- Simple, fast and lightweight riveting machines are used.

WHY USE STRUCTURAL RIVETS?

Bralo structural rivets are the ideal solution for reliable joints, due to their high tensile and shear strength.

In addition, Bralo has different types of structural rivets to adapt to different applications and thus offer the best fastening result in heavy-duty applications.

IN WHICH SECTORS OR INDUSTRIES?

Structural fasteners are used in the automotive industry, construction and various industries such as air conditioning, railways, lifting and renewable energies.

ARE STRUCTURAL RIVETS STRONG?

The main benefits of structural rivets are high strength, providing reliability and, in addition, drill hole filling, which withstands high stresses and external vibrations.

WHAT MATERIALS ARE RIVETED?

The materials to be riveted would be aluminum, steel and stainless steel metals, and also for joining metals to plastics.