How to choose a BRALO manual riveter?

The range of manual riveting machines is wide and, therefore, here we propose some recommendations to find out which one suits your needs.

We present what a riveter is, the types of BRALO riveters and the differences depending on the work you are going to do:

WHAT IS A MANUAL RIVETER?

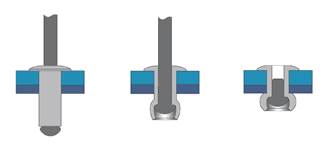

A hand riveter is a machine that allows you to set rivets or rivet nuts to join materials permanently.

The hand riveter pulls on the rivet stem to deform its head, thereby filling the hole and the materials together.

FACTORS FOR CHOOSING A MANUAL RIVETER

To choose the manual riveter that suits your needs, you must take into account the following recommendations: – The number of rivets to place.

– The effort to make.

– The size of rivets to place according to thickness and materials.

TYPES OF MANUAL RIVETING MACHINES FOR RIVETS

As we have mentioned, a manual riveter differs by the type of size of the rivet and also by the number of rivets to place:

The manual riveting machines that we can find at BRALO are of a high variety with the aim of adapting to different needs.

– Small manual lever riveter,

it is the one intended for repair work where it is required to install a small number of rivets.

These BRALO manual riveting machines place small diameter rivets, from 2.4 to 5.0 mm, that is, for holes less than 5 mm.

The riveting machines that BRALO offers are the BM-45, BM-75 and BM-85, the latter has an intermediate lever multiplier effect to reduce effort.

o The body of these manual riveters is made of cast aluminium.

o Its lever is made of steel strip.

o Rubber grips offer an ergonomic grip for easy riveting.

o It has steel inserts in threaded areas.

o They have a set of nozzles and a key to change them.

o 2.4, 3.0, 4.0 and 4.8/5.0 nozzles.

– Manual bellows riveter

is intended for professional work where rivets are placed continuously.

The BM-68 is a manual riveter that works by pushing the spring with one hand, therefore, a greater force is exerted.

o The nozzle holder is longer to allow access to tighter job sites.

o Its handle is made of high-density cast aluminum for greater resistance.

o Its plates are part of the spring and are made of steel strip, therefore, they give it great resistance.

o It has nozzles from 3.0 mm to 6.4 mm.

– Large manual lever riveting machines,

they are ideal for continuously riveting fasteners in professional workshops.

The BM-92 features a high quality lever, body and mount, ergonomic grips and 3.0 to 5.0mm nozzles.

The BM-160 and BM-164 manual riveting machines are riveting machines for professional use as they stand out for their great resistance.

o The main body is made of high-density aluminum and therefore the weight of the machine is reduced.

o Its levers and anchor are made of high quality steel.

o They have ergonomic handles.

o It has a stem collector, in this way a clean work area is achieved.

o The BM-160 almost effortlessly rivets 3.0 to 4.8 mm rivets, including structural rivets, and 5.2 mm S-clover (specially for soft materials)

o The BM-164 quickly places 4.8 to 6.4 rivets, as well as 6.4 mm S-clover, Hardgrip and Hardlock rivets.

FACTORS FOR CHOOSING A MANUAL RIVETING MACHINE FOR RIVET NUTS

To choose the manual riveter that places insert nuts, the following factors will be taken into account: – The metric size of the nut that we want to place. – The effort of the operator.

TYPES OF MANUAL RIVETING MACHINE FOR RIVET NUTS

At BRALO we have different types of manual riveting machines that are intended for small and large metrics, in addition to having accessories to place stud nuts.

– Small manual riveter,

it is the T-105, a light lever machine made of steel, ideal for placing a small number of nuts. This riveting machine has males and nozzles to place from M-3 to M-6.

– The large manual riveting machines

are the TR-308 and TR-312, also high-level professional machines that reduce effort thanks to their multiplier effect.

These are lever machines, with the main body made of high-density cast aluminum that provides strength and reduced weight.

Characteristic

o The TR-308 insert nuts from M-3 to M-8 in addition to having accessories to place stud nuts.

o The TR-312 fits nuts from M-6 to M-12

For any questions, contact BRALO and we will answer your questions about how to choose the right manual riveter for your job.

Rivets or insert nuts are solid and highly durable fasteners, being more reliable than other threaded options that lose efficiency.